NONWOVEN FABRIC

As a non woven fabric manufacturer of disposable sanitary products, we offer high-quality spunbond nonwoven, spunlace nonwoven, sms nonwoven, hot air through nonwoven, and elastic nonwoven, that are designed to meet the unique requirements of our customers. Choose our nonwoven fabrics for your hygiene products and experience the benefits of quality materials that are tailored to your specific requirements.

NONWOVEN FABRIC TAILORED TO YOUR INDUSTRY

Baby Care

Feminine Care

Incontinence Care

Pet Care

We can help you to select ideal nonwoven fabrics! Request a Consultation ➔

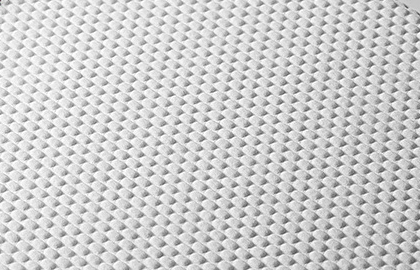

HOT AIR THROUGH NONWOVEN FABRIC

Hot air through nonwoven fabric is a type of nonwoven fabric created by blowing hot air through a fibrous web. The hot air fuses the fibers together to create a material that is strong, durable, and breathable. The advantages of hot air through nonwoven fabric include its high strength, durability, and breathability, which make it ideal for use in a wide range of applications, including hygiene products, medical products, etc.

Hot Air Through Nonwoven Fabric

Embossed Hot Air Through Nonwoven Fabric

Perforated Hot Air Through Nonwoven Fabric

ADL Nonwoven Fabric

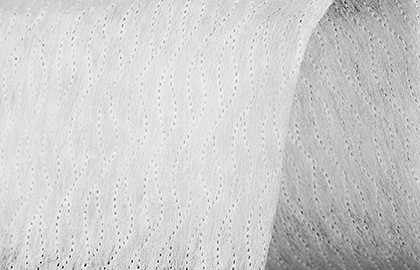

SPUNBOND NONWOVEN FABRIC

Spunbond nonwoven is made from thermally bonded, continuous filaments of synthetic polymers such as polypropylene. The fabric is formed by melting the polymer and extruding it into filaments, which are then laid down randomly and bonded together with heat and pressure. They can be perforated and embossed through various processing methods to meet different requirements of customers.

Hydrophilic Spunbond Nonwoven Fabric

Hydrophobic Spunbond Nonwoven Fabric

SMS SMMS SSMMS Nonwoven Fabric

Embossed Spunbond Nonwoven Fabric

Perforated Spunbond Nonwoven Fabric

THE FAQS YOU MIGHT WANT TO KNOW

These frequently asked questions mention almost answers you might want to know before buying nonwoven fabrics. We hope these informations could help you make a better decision.

What is nonwoven fabric?

Nonwoven fabric is a type of material that is produced by bonding fibers, without weaving or knitting them together. It is made from a variety of materials including polypropylene, polyester, and rayon. Nonwoven fabric is commonly used in hygiene products, such as diapers, feminine hygiene products, and wet wipes, because of its absorbency, softness, and other desirable properties. Nonwoven fabric can be manufactured in a wide range of weights, thicknesses, and densities to suit various applications. It is known for its versatility and can be engineered to have specific properties, such as absorbency, hydrophilic, hydrophobic, strength, softness,or breathability.

How is nonwoven fabric made?

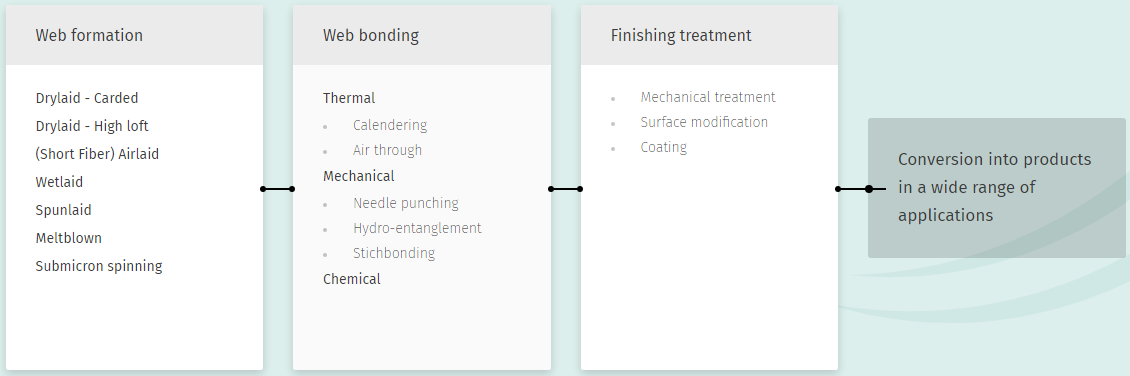

While there are different approaches to nonwoven fabric production, the process generally involves three stages: web formation, web bonding, and finishing treatment.

Web formation involves assembling fibers or particles into a sheet or web. This can be done using various methods, such as carding, air laying, wet laying, or spinning. The choice of method depends on the type of fibers, the desired properties of the final fabric, and the intended application.

Web bonding is the process of fusing the fibers in the web together to create a cohesive fabric. There are several methods for web bonding, including mechanical, thermal, and chemical bonding. Mechanical bonding involves using needles, water jets, or other mechanical means to entangle the fibers and create a strong bond. Thermal bonding involves using heat and pressure to melt the fibers together, while chemical bonding involves using adhesives or binders to bond the fibers together.

Finishing treatment is the final stage of nonwoven fabric production. This involves applying various treatments to the fabric to enhance its properties or modify its appearance. Finishing treatments can include calendering, coating, laminating, or printing. Calendering involves compressing the fabric to improve its smoothness and strength. Coating involves applying a layer of material to one or both sides of the fabric to enhance its properties. Laminating involves bonding two or more layers of nonwoven fabric or combining nonwoven fabric with other materials to create a composite material. Printing involves adding designs or patterns to the fabric.

Overall, nonwoven fabric production involves a series of processes that can be customized to produce fabrics with specific properties and applications. The web formation, web bonding, and finishing treatment stages are critical to creating a functional and high-quality nonwoven fabric.

What is Hot Air Through nonwoven fabric?

Hot air through nonwoven fabric is one type of thermal bonding nonwoven fabrics, which is produced by passing heated air vertically through a fiber web after carding, causing the lower melting point fiber or polymer powder to melt rapidly and reinforce the fiber web after cooling. The resulting fabric has a soft and fluffy texture, excellent liquid absorption properties, and good breathability. The most common fiber is ES bicomponent fiber (PE/PP or PE/PET), including 1.2D, 1.5D*38mm, 3D*40mm, 3D*51mm, and 6D*64mm. Hot air through bonding nonwoven fabric is commonly used in a variety of applications, including personal hygiene products(diapers and sanitary napkins), filtration materials, wipes, etc.

What is PP Spunbond nonwoven fabric?

PP Spunbond nonwoven fabric is produced using long, continuous fibers that are spun and dispersed directly into a web by either deflectors or air streams, resulting in faster belt speed and lower production costs. This type of fabric is typically made from polypropylene (PP) and is naturally hydrophobic, but can also be treated to be hydrophilic and used as a top sheet in disposable hygiene products. Spunbond nonwoven fabric can be combined with other nonwoven materials to create layered products such as SS (spun-spun), SSS (spun-spun-spun), or SSSS (spun-spun-spun-spun) nonwoven fabrics, which have more even fibers and improved performance. These fabrics are commonly used in the disposable hygiene and medical industries, including products such as baby and adult diapers, feminine sanitary napkins, panty shields, under pads, face masks, surgical gowns, isolation gowns, and more.

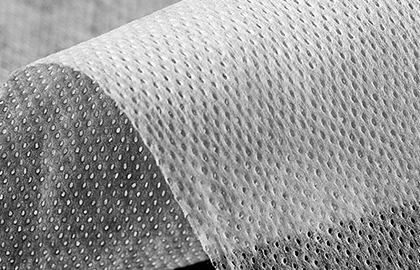

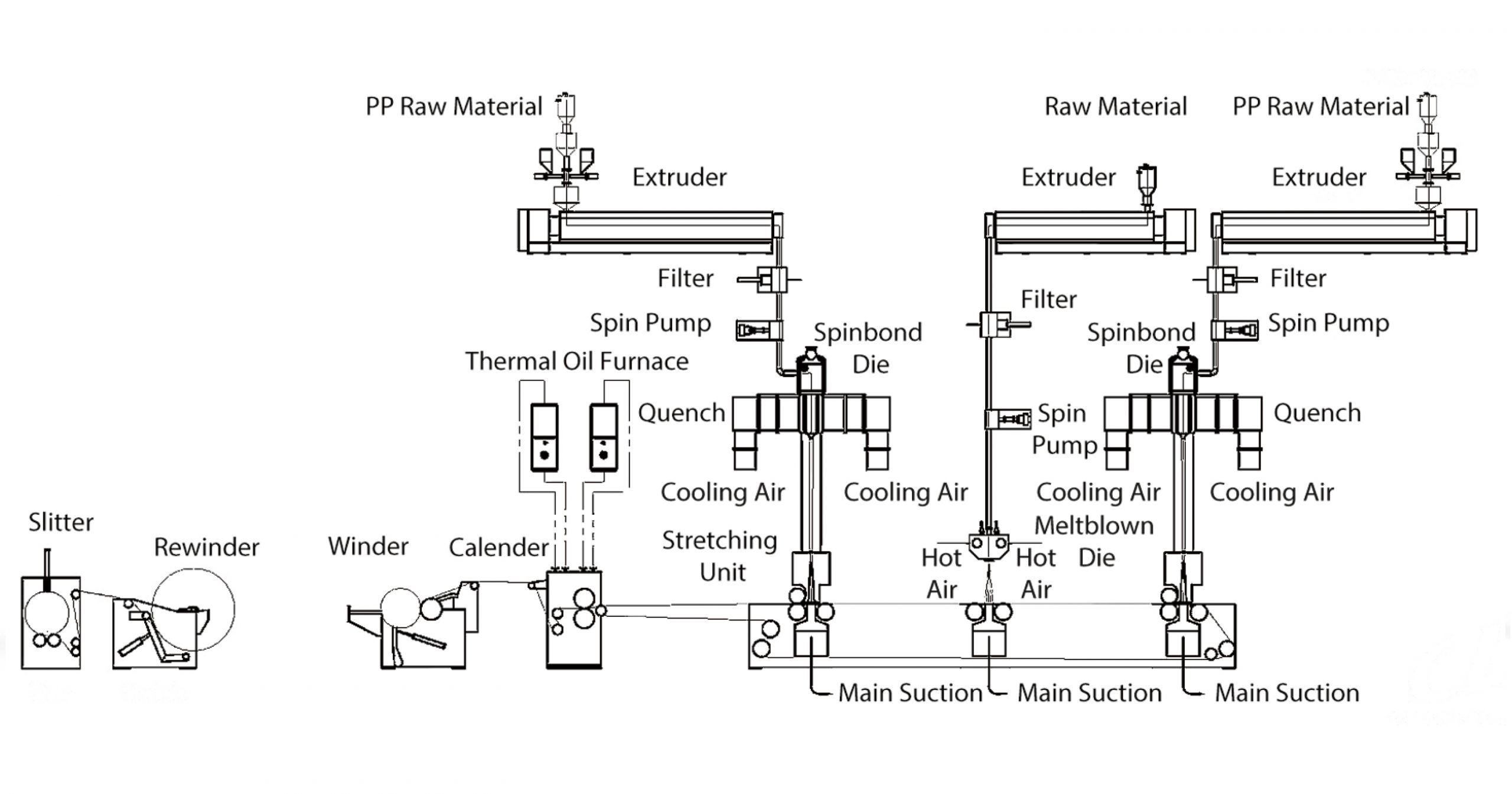

What is SMS Spun-melt nonwoven fabric?

Spun-Melt nonwoven fabric is a type of nonwoven fabric that is made by spinning and melting a thermoplastic polymer to form a web. The process involves first melting the thermoplastic polymer and then extruding it through spinnerets to create fine filaments. The filaments are then cooled and stretched to create a continuous web of fibers. The web is then bonded using heat, pressure, or chemicals to create a strong and durable fabric.SMS stands for Spunbond-Meltblown-Spunbond, which is a three-layered fabric composed of spunbond polypropylene layers on the top and bottom and a meltblown polypropylene layer in the middle. This type of nonwoven fabric is commonly used in medical and hygiene products such as disposable diapers,isolation gowns or surgical gowns.

What is Spunlace nonwoven fabric?

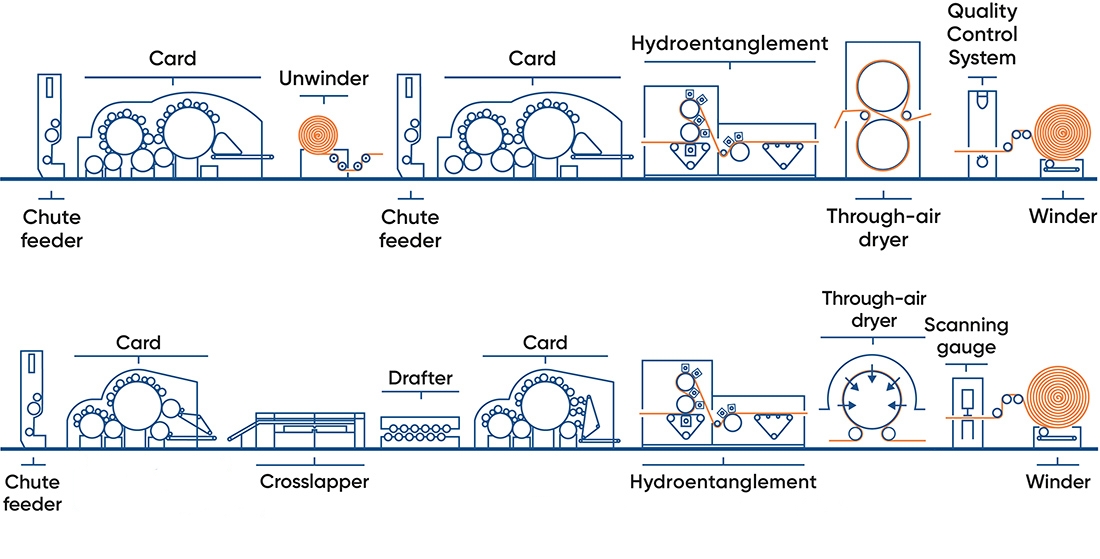

Spunlace nonwoven fabric is a type of nonwoven fabric that is made by entangling fibers together using high-pressure water jets. The fibers used to make spunlace nonwoven fabric can be natural (such as cotton, bamboo, or flax) or synthetic (such as polyester, rayon, or nylon). The fibers are first carded or air-laid to form a loose web, which is then fed through a series of fine water jets that spray high-pressure water onto the web. The water jets cause the fibers to entangle and form a strong, durable fabric with a smooth surface.The entangling process used to make spunlace nonwoven fabric is sometimes called hydroentanglement or spunlacing. It is a mechanical process that does not involve any chemicals, adhesives, or heat, which makes it environmentally friendly and safe for use in applications where contact with human skin is required. Spunlace Nonwoven fabric is widely used in wet wipes, disposable towels, beauty facial masks, cotton pads, etc.

GET A QUICK QUOTE

Simply click below button,and get your free , no obligation quotation today!

Nav. Links

Products

Reach Us

- info@mocarehygiene.com

- +86 13413926366

- www.mocarehygiene.com

Copyright © 2023 MOCARE COMPANY | All Rights Reserved | Powered by MOCARE HYGIENE